I think I’m starting to get to grips with the strakes now, having gradually figured out their shape, how they change as you get further from the keel etc…

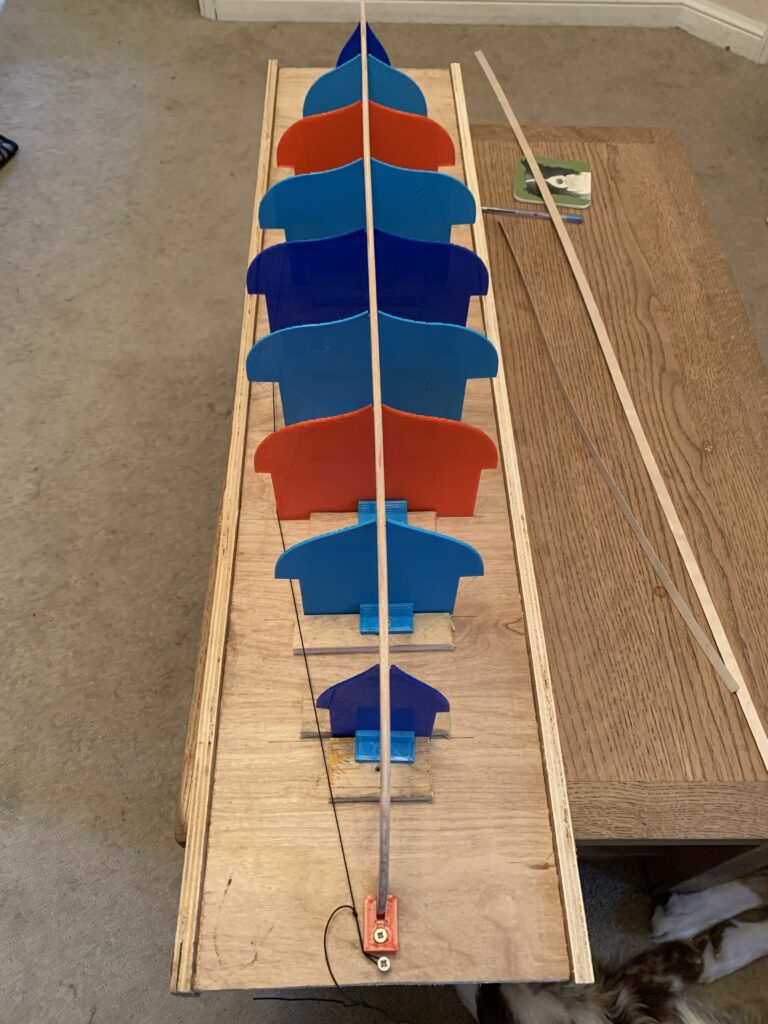

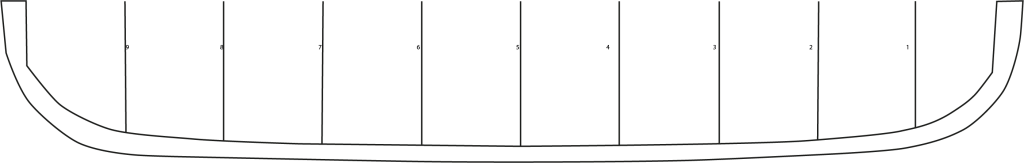

I’m nearly at the half way stage now with 7 of the 16 strakes in place on each side. The hull is starting to take on the shape and lines. Each strake has to be shaped to form the overlapping shapes at the bow and stern where they are nearly vertical. At the same time they need to allow the bottom of the hull to be almost flat for at least the first 8-9 strakes.

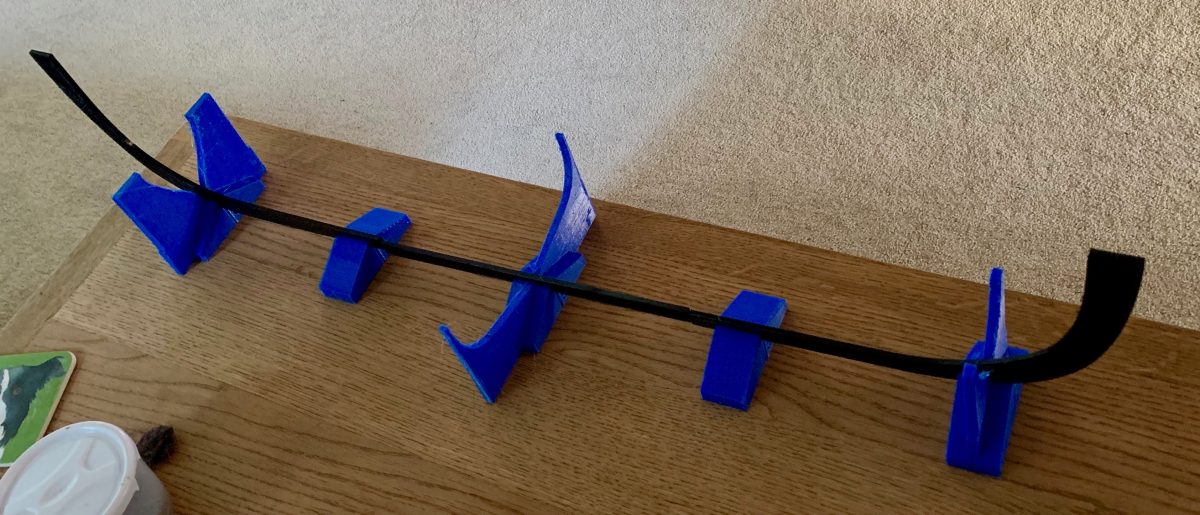

The first strakes used a straight edge from bow to stern, utilising the natural flex in the wood to form the correct shape. As I’ve moved further from the keel though I’ve needed to add a curve to the edge closest to the keel. Until the centre of the hull approaches the water line, the curve will need to increase for each strake.

I’m tracing the outline of each strake as I complete them so I can easily make replacements. I will probably end up digitising them once I’m happy with the final hull.